CUSTOMER PROJECT

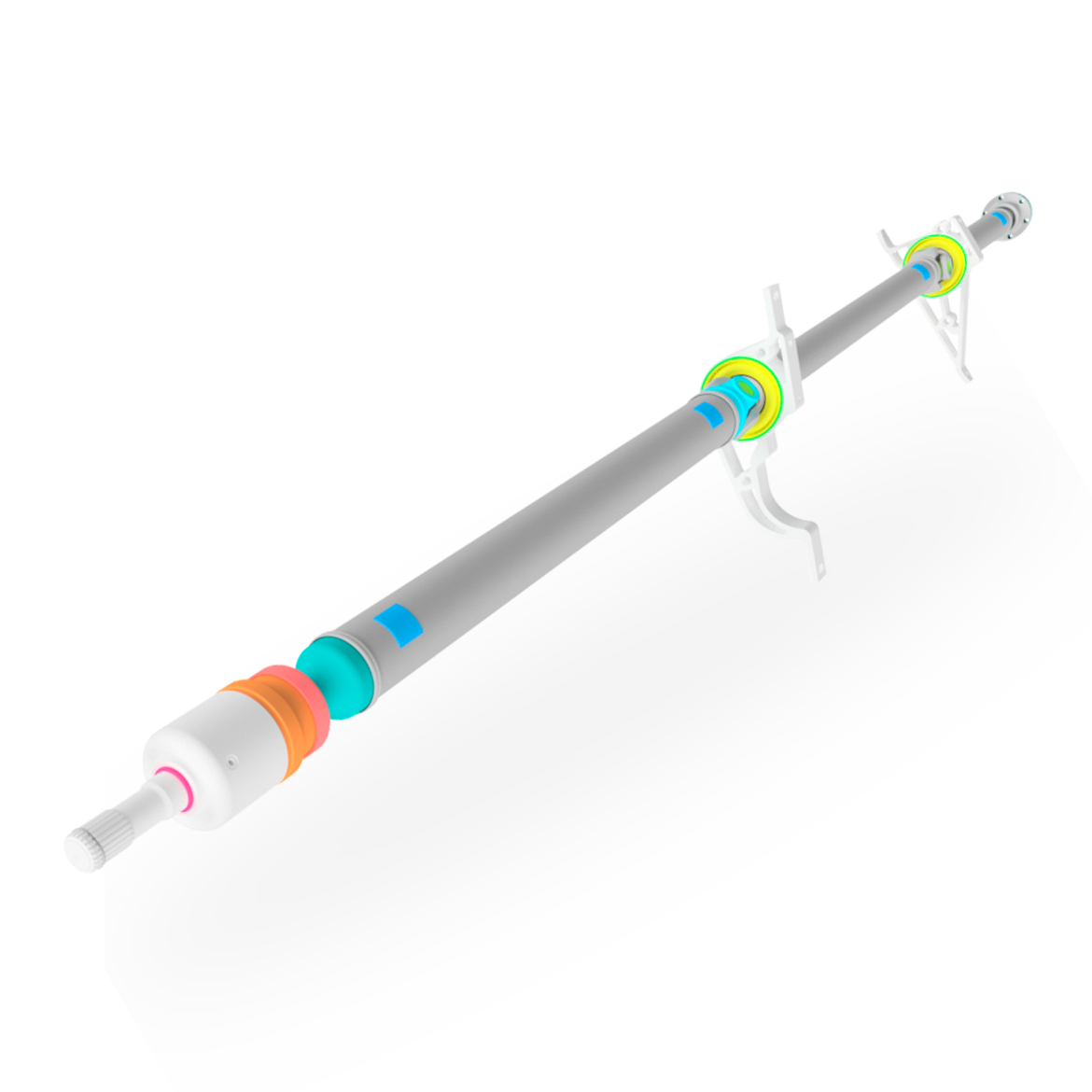

Drive universal shaft assembly

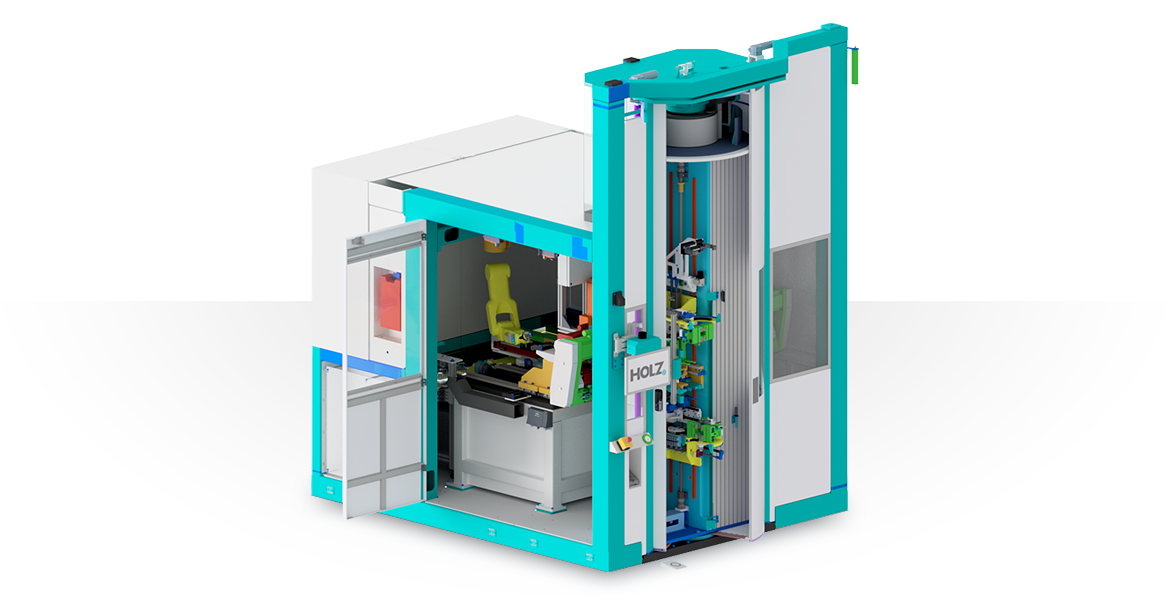

ASSEMBLY

CHECK

PROCESS DATA MANAGEMENT

Your contact person for automation

Jürgen Holz

Feel free to contact me! I will gladly provide you with information on automation and your options in this area:

Tel.: +49 (0) 7191 / 3432-100 | juergen.holz@holz-automation.de

FURTHER HIGHLY EFFICIENT AUTOMATIONS

FURTHER HIGHLY EFFICIENT AUTOMATIONS

Customer Projects

WE CAN STILL DO A LOT MORE…

Get in touch now.

We will gladly inform you about further innovative high-tech solutions from our company.